As the demand for high-quality, health-conscious oils continues to rise, accurately measuring the Safflower Oil Content is more crucial than ever. For agribusinesses, food manufacturers, and researchers, reliable, efficient, and rapid oil content measurement is key to ensuring product consistency, quality, and economic value.

Spinlock, a leader in magnetic resonance technology, offers a cutting-edge solution for measuring safflower oil content through its SLK 200 NMR equipment. This state-of-the-art system provides a non-destructive, rapid, and precise method for oil quantification, making it an invaluable tool for businesses seeking to streamline their analysis process. Below, we explore how Spinlock’s SLK 200 enhances safflower oil content measurement, ensuring accuracy, efficiency, and reliability.

1. Why Choose NMR for Safflower Oil Measurement?

Nuclear Magnetic Resonance (NMR) spectroscopy is an advanced analytical technique that has gained significant traction in various industries, including agriculture and food production. Unlike traditional methods that require physical extraction of oil, NMR technology offers several advantages:

- Non-destructive: NMR allows for the direct measurement of oil content without altering the sample, preserving it for further use.

- Speed: Results are available in seconds, significantly reducing analysis time compared to traditional methods like Soxhlet extraction.

- High Precision: NMR provides a high degree of accuracy, allowing for reliable measurements with minimal error.

- No Hazardous Solvents: Unlike chemical and solvent-based methods, NMR avoids the use of potentially harmful chemicals, making it a safer and more environmentally friendly choice.

2. The SLK 200: Designed for Precision and Performance

The SLK 200 from Spinlock is engineered specifically to meet the needs of industries where oil content measurement is critical. With a user-friendly interface and cutting-edge features, the SLK 200 offers unmatched performance for safflower oil analysis.

Key Features of the SLK 200:

- High Sensitivity: The SLK 200 provides exceptional sensitivity for detecting and quantifying the oil content in safflower seeds, even at low concentrations.

- Rapid Results: With its fast-scanning capability, the SLK 200 can deliver results in a matter of minutes, significantly improving workflow efficiency.

- Minimal Sample Preparation: The system requires minimal sample preparation, reducing the time spent on pre-processing and increasing overall throughput.

- Accurate Oil Quantification: Using NMR’s precise measurement of hydrogen nuclei, the SLK 200 delivers highly accurate oil content data with no sample degradation or loss.

- User-friendly Interface: The intuitive design of the SLK 200 ensures that even those with minimal NMR experience can operate the system effectively and get the results they need quickly.

3. How SLK 200 Works for Safflower Oil Content Measurement

The SLK 200 operates on the principle of Nuclear Magnetic Resonance (NMR), which measures the interaction of atomic nuclei, particularly hydrogen nuclei (protons), with an applied magnetic field. This allows the system to analyze the molecular composition of safflower seeds, specifically the oil content.

The Process:

- Analysis configuration: Spinlock’s software interphase is simple and user-friendly. A quick sample identification and experiment configuration is performed prior to starting the analysis.

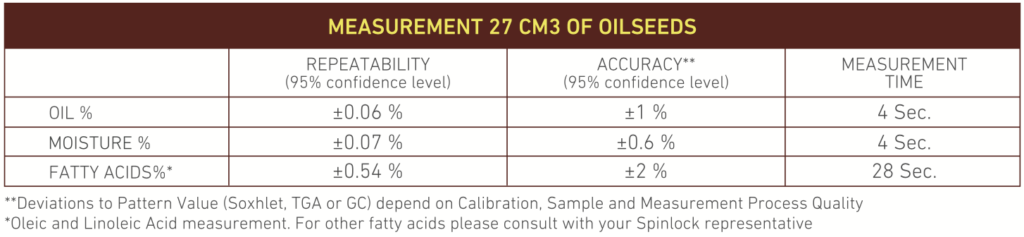

- Sample Placed on Tube: a 27cm3 sample (about 10g) is placed inside a sample holder tube and then weighed on a laboratory scale. When the Automatic Balance is used the weight is captured automatically by the SLK 200 Software.

- Analysis Run: After the Sample holder tube is inserted into the equipment, the operator will click on “Run Analysis” to start the measurement.

- Analysis and Results: The SLK 200’s software interprets the data and provides a detailed, accurate reading of the oil content, which is displayed in real-time. Measurement time is 4 to 7 seconds for Oil content.

4. Advantages of Using SLK 200 for Safflower Oil Measurement

- Enhanced Efficiency: The SLK 200’s rapid and automated NMR scanning process allows for high throughput analysis, ideal for businesses with large volumes of safflower seed samples.

- Automatable: The SLK 200 can be fully automated buy using the SLK AS 30 – an Autosampler unique of its kind as it is the only Autosampler for tubes of 40mm diameter on the market. The SLK AS 30 picks up the sample, weights it on the scale and then takes the sample for measurement inside the SLK 200. A closed loop of up to 60 samples can be run with its 3-bench configuration.

- Safer operation and Reduced Costs: By eliminating the need for solvents, hazardous chemicals, and complex sample preparation, the SLK 200 reduces both direct and indirect operational costs, offering a safe and cost-effective alternative to traditional methods.

- Environmental Impact: Spinlock NMR’s non-destructive nature and solvent-free analysis make it an environmentally friendly choice for companies committed to sustainability.

- Reliable and Reproducible Results: With its high precision, the SLK 200 ensures consistent, reproducible results, providing greater confidence in oil content measurement.

- Versatility: While designed for safflower oil, the SLK 200 is a versatile tool that can be used to analyze a wide range of oil-bearing seeds and other agricultural products, making it a valuable investment for diverse applications.

5. Industries That Benefit from SLK 200

The SLK 200 NMR system is a powerful tool for several industries where safflower oil content plays a crucial role:

- Agriculture and Seed Producers: For Seed Companies, Traders, Crushers and Laboratories, the SLK 200 NMR System is a fundamental tool to value product and analyze quality in general.

- Food and Beverage Manufacturers: Companies involved in producing safflower oil-based products, such as cooking oils or health supplements, benefit from precise oil content data to ensure product quality.

- Research and Development: Research institutions and laboratories rely on NMR to conduct detailed studies on the chemical composition of safflower seeds and other oil-bearing crops.

6. Why Spinlock?

Spinlock has long been recognized as a leader in the field of magnetic resonance technology. With decades of expertise, Spinlock’s SLK 200 NMR system represents the pinnacle of precision, ease of use, and reliability in oil content measurement, together with great innovations unique to the Spinlock. Our commitment to excellence is evident in our support services, offering training, consultation, and after-sales assistance to ensure customers achieve the best results with our equipment.

7. Conclusion

In an increasingly competitive market, businesses that rely on safflower oil need the most efficient and accurate tools for measuring oil content. Spinlock’s SLK 200 NMR system provide a modern, reliable, and environmentally friendly alternative to traditional oil extraction methods. With its rapid analysis, high precision, and ease of use, the SLK 200 is the perfect solution for anyone seeking to enhance their safflower oil measurement process.

To learn more about how Spinlock’s SLK 200 can help you optimize safflower oil content measurement, visit Spinlock or contact our team for a demonstration today.